Say the words Audemars Piguet, and the Royal Oak instantly comes to mind. Indeed, the Royal Oak collection has become so synonymous with the brand, that when Audemars Piguet introduced the Code 11.59 by Audemars Piguet back in 2019, it sparked a wave of surprise - even resistance - within the watch community. Perhaps it was the initial shock of not seeing a new Royal Oak from Audemars Piguet, or the fact that the Code 11.59 by Audemars Piguet is so decidedly different from the Royal Oak that led to a sense of disconnect. However, through research for this article, I have found that while the aesthetics of the two collections is distinctly different, the approach to their creation is remarkably aligned. Underneath this veneer of Royal Oak or Code 11.59 by Audemars Piguet lies a core philosophy that I think has allowed Audemars Piguet to survive and thrive for as long as it has. The heart and soul of the brand lies in its complications. Long before the Royal Oak, Audemars Piguet was known for its pioneering spirit, a company built with tenacity and resilience, and an unwavering pursuit for excellence.

This year, Audemars Piguet celebrates its 150th anniversary, and to mark this momentous occasion, the brand has been releasing a series of exceptional timepieces throughout the year. From the most user-friendly perpetual calendar calibre to the introduction of smaller a 38 mm perpetual calendar, they even made flying tourbillons adorned with natural stone dials. Among these celebratory creations, one that, to me, symbolises the epitome of what the brand stands for. In their eternal quest for watchmaking innovation, they unveil the Royal Oak “Jumbo” Extra-Thin Self-winding Flying Tourbillon Chronograph RD#5. This latest addition to the RD series takes one of the oldest watchmaking complications, the chronograph, and looks at it from a distinctly futuristic lens. The result is an unexpected update of a classic function. At first the innovation may not be immediately apparent, but the technical ingenuity behind it is brilliant.

To understand how Audemars Piguet arrived at the RD#5, one must first look back. Now, on the 150th anniversary of Audemars Piguet, we rewind the clock all the way back to the origins of the brand to understand how the founders incorporated the pioneering spirit into their eponymous brand, and how that founding philosophy has endured over a century and a half. In the 19th century, it was common for Swiss watchmakers to build a brand with a partner who was more well-versed in the commercial realm of things. In 1875, Jules Louis Audemars started his watchmaking workshop in Le Brassus, and by 1881, he had partnered with his childhood friend and neighbour Edward Auguste Piguet, and the brand Audemars Piguet was formalised and registered. The company was established in tumultuous times. There was strong competition from American watchmakers, and Swiss watchmakers were starting to industrialise their processes in response. Instead of following the trend, the two founders decided that they would instead focus on making one-off, complicated timepieces. Of the 52 watches they sold in 1882, 49 of them had complications. By 1899, most of the world’s complicated calibres were made in manufactures in the Vallée de Joux, and Audemars Piguet was at its heart. In fact, it was around this time that they made the Universelle pocket watch delivered to Union Glashütte, which remains one of the most complicated watches in the world with 1,168 components and presented 26 functions, including 19 complications.

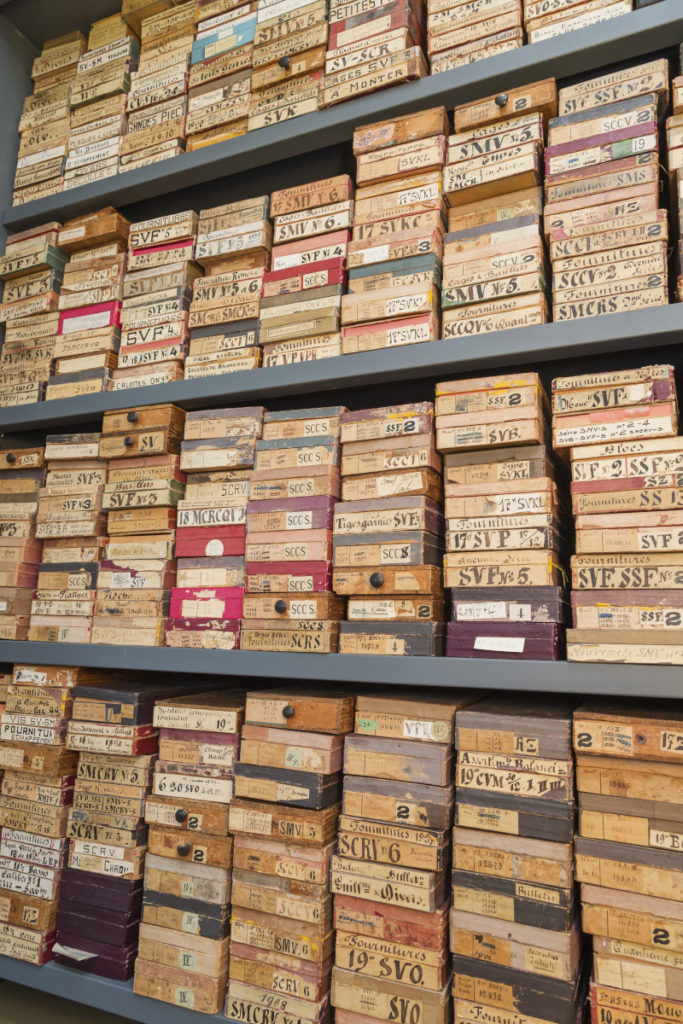

The path to greatness is rarely smooth - and Audemars Piguet's journey in no exception. The First World War broke out in 1914, which saw Audemars Piguet lose half its workforce to military service. And even as the founders passed on the reins to their successors and the next generation of Audemars and Piguet took to running the brand, they were followed by hardships every step of the way. In 1929 the stock market crash, which saw the Manufacture running at a loss for the next 15 years, and from 1939 to 1945, the Second World War once again brought production to a near standstill. Each crisis saw a sharp decline in watch sales. To make the most of the watchmaker’s available time, the manufacture tasked their watchmakers to develop manual watchmaking skills in anticipation of better days, a decision that continues to be the driving force behind Audemars Piguet’s watchmaking innovation.

It was only after the Second World War that Audemars Piguet experienced a new era of growth. In the hands of the second and third generation family members, the company’s production grew tenfold in the span of 20 years, producing 5,500 watches per year, and by 1971, it had an annual revenue of 10 million Swiss Francs. It was probably this level of success that prompted them to make the now world-renowned “most expensive steel watch in the world” – the Royal Oak. The Royal Oak was a result of yet another turning point in Audemars Piguet history where in 1966 they appointed the legendary Georges Golay as the Managing Director of the brand, and the first who did not come from the founding families. It was Golay who recognised the value of talented designers like Gérald Genta, and his overnight creation of the Royal Oak 5402 has become lore for the brand.

Even with the success of the Royal Oak, Audemars Piguet has constantly pursued watchmaking innovation. When the quartz era came along, the Manufacture responded with its own high-tech creation - reference 6001, powered by the "megaqwartz" Calibre 2510, in 1974. In the 1990s, under the direction of Steve Urquhart and Georges-Henri Meylan, Audemars Piguet contributed to the revival of mechanical watches with complications such as tourbillons, chiming mechanisms, chronographs, and Grand Complications. In the last 25 years, they have integrated their manufacturing capabilities and expanded them to what the brand is today.

The trajectory of how Audemars Piguet grew as a company is undoubtedly inspiring, but perhaps even more important is how the brand has managed to preserve the pioneering spirit instilled by its founders. In an interesting interview that the current CEO of Audemars Piguet, Ilaria Resta, gave to Revolution’s Wei Koh earlier in the year, she said the entry point into AP is not through iconic designs, but through complications, which is rare in the world of haute horlogerie. It sort of makes sense considering that complications were the focus when Jules Louis Audemars and Edward Auguste Piguet started the brand in 1881, but to keep complications as the heart and soul of a brand over 150 years, now that is no easy feat.

“This company’s philosophy is to leave no stone unturned and pursue all possible improvements based on research and practice.”

Le Journal Suisse d’Horlogerie, circa 1889

According to Resta, this pioneering spirit can’t be forced. And it is true; there is no formula to build a team that is instantly creative and can automatically and consistently push the boundaries of watchmaking. Especially when you consider that most of the principles of mechanical watchmaking used today haven’t been changed in the last century or so. This takes out of the box thinking, a daring to try and fail, and above all, the financial might to sustain these kinds of research and development projects. This exists within the infrastructure of Audemars Piguet. The Manufacture has departments dedicated to experimentation, on materials, calibres and finishing techniques which translate not only to novelties within the brand’s collections but also help perpetuate watchmaking as a whole. In that same interview, Resta described the brand's creative philosophy as a "playground" for innovation. Boundaries are defined by core brand values, but within, there is ample room for the thinkers and makers to manoeuvre. Also, leadership doesn’t place deadlines on their creations, which can sometimes be antithesis to the creative process.

Much of this freedom is made possible by the brand's independence. They are the only watchmaking company at this level that is still in the hands of its founding families. It is astonishing how, after 150 years and the tremendous growth the company has undergone, the representation of the founding families is still consulted on the future direction of the brand. And although since 1966 Audemars Piguet has been led by non-family members, Jasmine Audemars, great-granddaughter of Jules Louis Audemars and Olivier Audemars, great-grandson of Edward Auguste Piguet, still represents the interests of both the Audemars and Piguet families. The result of this ecosystem of innovation that Audemars Piguet has cultivated is a creative environment where designers and engineers are empowered to develop complications that challenge the conventions of watchmaking.

Nowhere is this more apparent than their RD (Research and Development) saga of watches. Their RD series is the brand’s platform to showcase their groundbreaking advancements in watchmaking. Each creation introduces a breakthrough in engineering or performance - solving longstanding horological challenges through innovation. It is a testament to the brand's commitment to pushing the boundaries of what is possible, not only for the brand itself, but for the advancement of the craft as a whole. The RD#1 (2015) ‘Supersonnerie’ dramatically improved the sound quality of minute repeaters, setting new acoustic standards for chiming watches. The RD#2 (2018) broke watchmaking records with the world's thinnest selfwinding perpetual calendar at just 2.89 mm thick. The RD#3 (2022) was the first "Jumbo" to be equipped with a selfwinding flying tourbillon, powered by the ultra-thin Calibre 2968 (first released in 39 mm, then in 37 mm) and equipped with an innovative high-amplitude escapement. Next, came the RD#4 (2023) Code 11.59 by Audemars Piguet Ultra-Complication Universelle. The reference is the Universelle pocket watch, which we mentioned earlier in this story, and the AP Calibre 1000 for the RD#4 incorporated 40 functions, including 23 complications and yet was still designed to be easy to use and comfortable to wear.

Which brings us to the current chapter in the RD saga, RD#5. For the collectors, this new launch from Audemars Piguet features a brand-new movement, Calibre 8100. It is the first time in the Royal Oak “Jumbo”’s 50-year history that it is equipped with both a flyback chronograph (with an instant minute jump) and a flying tourbillon, and the watch is limited to only 150 pieces worldwide. For the true watch connoisseurs however, the real gem in the RD#5 lies in the chronograph complication which has been totally redesigned by Director of Watch Conception at Audemars Piguet, Giulio Papi and his team.

Let’s start then with the push-pieces. A typical pusher on a chronograph usually requires a significant amount of pressure to engage, and its subsequent click may not be the smoothest or most enjoyable experience when compared to the finesse of everything else in a well-finished haute-horlogerie timepiece. As Papi explains, “Their travel – that is, the distance they must be pressed – is often 1 mm or more and requires a force of around 1.5 kilograms. Our aim was to reduce these values to enhance the client experience, drawing inspiration from smartphone buttons which typically have a travel of 0.3 mm and require 300 grams of force.” This is exactly why, when you look at the images of the watch, you see sleek buttons instead of the traditional pushers found on the brand’s chronographs.

The ingenious solution to enable this short-travel, low-force push-pieces comes via a new patented mechanism which replaces the conventional heart piece and hammer with a rack and pinion system. This clever system in the Calibre 8100 stores the energy in the rack, which keeps the gear train under tension, preventing the chronograph hands from shuddering. And this then eliminates the need for a friction spring. The friction spring in conventional chronographs acts as a constant brake during operation and resetting of the chronograph, and with the rack, the energy is stored rather than dispersed, so with a light touch of the pushers, this energy can be re-used to perform the necessary chronograph functions.

“Think of the traditional chronograph as a car driving with the handbrake on. With Calibre 8100, the handbrake is gone, and the car is now tied to an elastic band when it leaves the garage. This elastic band will then be used to bring it back to the garage. The energy that used to be lost due to the friction of the handbrake is now stored within the elastic,” says Giulio Papi. “When resetting the chronograph, the stored energy is released, and the hand returns to its position in less than 0.15 seconds. A great deal of work has been carried out to understand the behaviour of the hands so that the reset is almost imperceptible to the eye, while delivering an instantaneous minute jump – a highly coveted feature by collectors.”

One of the reasons that the Jumbo has never had a chronograph and a flying tourbillon combination was the challenge of keeping the movement within the constraints of the smaller case size. However, as we have established earlier with the RD#3, the lessons learned through that project can now be implemented in the RD#5 and improved upon. To further preserve the Jumbo proportions, the designers used glass box sapphire crystals both on the dial side and caseback, which are totally flat on the outside but hollowed out on the inside to give the movement just that extra bit of space. Additionally, the Calibre 8100 also utilised a peripheral oscillating weight in platinum, both to reduce the thickness of the watch and allow for an unhindered view of the movement. It is fascinating to note that both the RD#3 and RD#5 have the same 8.1 mm thickness, even with the added chronograph on the RD#5, demonstrating how Audemars Piguet continues to develop its watchmaking savoir-faire over time.

The case combines the tried and tested titanium material with the rare use of Bulk Metallic Glass (BMG). BMG was first discovered in the 1960s and has been used in the military and space sectors. These are metallic alloys that, when rapidly cooled, will take on properties similar to glass, turning it into a high-strength material with an amorphous structure Composed of over 50% palladium, what this means in layman’s terms is that the material can offer exceptional resistance to wear and corrosion, along with a distinctive reflective sheen. Audemars Piguet first introduced this material on their watches in 2021, with the unique Royal Oak “Jumbo” Extra-Thin (ref. 15202XT) created for Only Watch, and made its way into their production models in 2023. For the RD#5, BMG is used for the pushers and the connecting links on the bracelet, which allows for a fantastic interplay of light as it bounces off the polished and brushed finish of the various materials.

With the Royal Oak “Jumbo” Extra-Thin Selfwinding Flying Tourbillon Chronograph RD#5, the next chapter of Audemars Piguet history has been written, and it comes at the perfect time when the brand is celebrating 150 years of existence. As the brand often iterates how it constantly strives for perfection, and because the concept of perfection is near impossible to achieve, we can surmise that for Audemars Piguet, they will never truly be able to achieve their final goal and can only perpetually strive towards this unattainable achievement, getting as close as possible to the elusive perfect timepiece. And this will set their course, allowing them to move headstrong into the unknown for the years, decades and perhaps even centuries to come.